Where are you located?

3991 Fondorf Drive

Columbus OH, 43202

Contact Us

Are you open for public tours?

The shop is closed to the public, however we do offer tours for interested clients. Please call us if you are in the neighborhood and interested in seeing what we do.

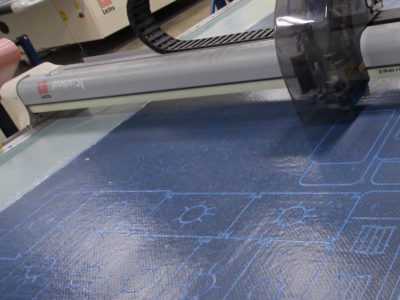

What types of composite fabric material do you keep in stock?

We stock over 500 linear yards of pre-preg lamina at all times. We can also order in custom fabric blends for specific requirements.

3k / 12k Weave Prepreg

4201m-285 Kevlar

Fiberglass

Xylon composite

Unidirectional dry-carbon

Film Adhesive

What is pre-preg?

Pre-preg is a term for “pre-impregnated” composite fibers where a matrix material, such as epoxy, is already present. The fibers often take the form of a weave and the matrix is used to bond them together and to other components during manufacture. The matrix is only partially cured to allow easy handling; this is called B-Stage material and requires cold storage to prevent complete curing. B-Stage pre-preg is always stored in cooled areas since heat accelerates complete polymerization. Hence, composite structures built of pre-pregs will mostly require an oven or autoclave to cure.

Pre-preg allows one to impregnate the fibers on a flat workable surface, or rather in an industrial process, and then later form the impregnated fibers to a shape which could prove to be problematic for the hot injection process. Pre-preg also allows one to impregnate a bulk amount of fiber and then store it in a cooled area (-20 C) for an extended period of time to cure later. Unfortunately the process can also be time consuming in comparison to the hot injection process and the added value for pre-preg preparation is at the stage of the material supplier.

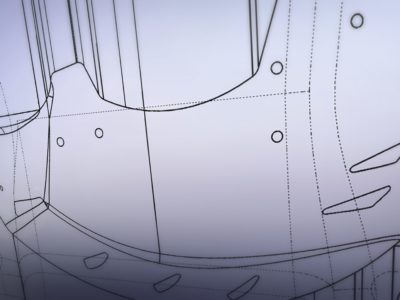

Are you able to manufacture molds and tooling?

Wolf Composites manufactures tooling for many diverse industries. Please see the services page to view all of the solutions Wolf has to offer.

Our Services

Can you make just one part?

Yes, no project is too big or too small for Wolf Composites. From single prototypes to full scale 1000 piece production runs, we have you covered. Contact us to start your project today. Request a project quote directly through our website.

Request a Quote

Do you do carbon repairs?

In previous years, our company specialized in carbon repairs. Please call to discuss a repair project. Not all pieces can be repaired.